Batch

Production, Introducing A Major Advancement in Rapid Prototyping

--- MDX-540

MODELA

PRO II MDX-540 Features:

- Precision

benchtop milling machine produces high-quality parts and

models using Roland¡¦s Subtractive Rapid Prototyping (SRP)

technology

- Simple

on-screen menus and operation panel make setup and production

easier than ever

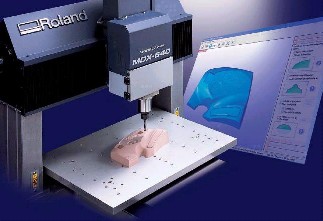

- Cutting

area of 500 mm (X) x 400 mm (Y) x 155 mm (Z) (19.6 (X) x

15.7 (Y) x 6.1 (Z) in.) accommodates larger prototypes

- Advanced

software optimizes your 3D CAD data for flawless molds and

parts

- In-house

milling shortens the design/development cycle and lowers

product development costs

User-Friendly

Operation User-Friendly

Operation

Designed from the ground up for ease of use, the

MDX-540 features a handy control panel that simplifies

the setup and production processes by strategically

grouping the most commonly used settings. Using a

jog-dial, you can quickly and easily reposition tools and

adjust spindle speeds without interrupting the milling

process. For other settings, simply access the

MDX-540¡¦s on-screen operation panel featuring clear,

easy-to-navigate icons.

Powerful

Options for High Production Demands

Four powerful options let you build on your MDX-540 for even

greater performance and unattended operation.

These include an Automatic Tool Changer (ATC), rotary axis

unit, T-slot table and safety cover. The optional ATC holds

up to four tools while the rotary axis unit facilitates 360

degree and multiple-surface cuts.

Able

to Mill a Wide Variety of Materials

With the MDX-540, you can produce molds and parts for small

lot production quickly and inexpensively from a wide range

of materials, including chemical woods, resin, ABS and non-ferrous

metals such as aluminum, brass and copper.

Optional:

|