MDX-15/20:

(3D Scanning & CNC Milling Machine)

This is a desktop milling machine with 3D scanning and CNC

milling functions. Many jewellers use this device to perform

milling for its size is small, and it is easy to use and works

very well with a variety of popular 3D CAD and computer graphics

software programs in the market. In addition, because of its

attractive low prices, many manufacturers have purchased three

sets or above of this device for production.

|

|

|

| MDX-15 |

MDX-20 |

|

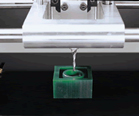

Work

piece produced by the MDX-15/20.

The

MDX-15/20 mills ABS, acrylic, woods, plastic, styrene

foam, chemical wood, modeling wax, and light metals

such as aluminum and brass. |

|

With

the milling spindle unit, the MDX-15/20 enables users

to complete the milling operation in the shortest time. |

|

|

The

MDX-15/20 provides cutting tools which can be used to

mill directly on materials like modeling wax, wood,

chemical wood, plastic and aluminum. It is especially

suitable for design and making of prototypes. |

|

|

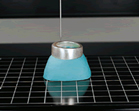

Due

to the precision of its Roland Active Piezo Sensor (R.A.P.S.)

technology, the MDX-15/20 scans a wide range of objects. |

|

|

Simply

input the resolution (from 0.05mm to 5.00mm) and the

device will scan and digitize the data automatically.

It

can run completely unattended for 24 hours. |

Application

software included

| Dr.

Picza

Dr.

PICZA Scanning Software features a dynamic graphic display

and diverse editing functions. The scanning data can

be stored in its original format, or exported in DXF,

IGES, VRML, or as Point Cloud data (ASCII).

|

|

| MODELA

Player

Users

can input CAD file or scanned data to perform CNC milling.

With its user-friendly interface, even the first-time

users can master the skill of NC programming in an hour

to carry out the production. |

|

Feature:

| |

MDX-20 |

MDX-15 |

| XY

table size |

220

mm (X) x 160 mm (Y) ( 8-5/8 in. x 6-1/4 in. ) |

170

mm (X) x 110 mm (Y) ( 6-11/16 in. x 4-5/16 in. ) |

|

Max.

operation area |

203.2

mm (X) x 152.4 mm (Y) x 60.5 mm (Z)(8 in. (X) x 6

in. (Y) x 2-3/8 in. (Z)) |

152.4

mm (X) x 101.6 mm (Y) x 60.5 mm (Z)(6 in. (X) x 4

in. (Y) x 2-3/8 in. (Z)) |

| Max.

table load weight |

1000

g (2.2 lb.) |

500

g (1.1 lb.) |

| Interface |

Serial

(RS-232C) |

| Control

keys |

STANDBY

key, VIEW key, TOOL-UP key, TOOL-DOWN key |

| LED |

SCANNING

MODE LED, MODELING MODE LED, VIEW LED |

| Power

Pack |

Exclusive

AC adapter (DC+19V 2.1 A) |

| Acoustic

noise level |

Standby

mode : under 35 dB (A) Operation mode (not cutting)

: under 70 dB (A) (According to ISO 7779) |

|

External

dimensions |

476.8

mm (W) x 381.6 mm (D) x 305 mm (H)(18-13/16 in. (W)

x 15-1/16 in. (D) x 12-1/16 in. (H)) |

426

mm (W) x 280 mm (D) x 305 mm (H)(16-13/16 in. (W)

x 11-1/16 in. (D) x 12-1/16 in. (H)) |

| Weight

(unit only) |

13.7

kg (30.2 lb.) |

9.6

kg (21.2 lb.) |

| Operation

temperature |

5

to 40 (41 - 104 F) |

| Operation

humidity |

35

to 80 % (no condensation) |

|

Accessories |

AC

adapter: 1, power code: 1, Roland Software Package

CD-ROM: 1, spindle unit: 1, sensor unit: 1, cap screw

M4x15 : 4, tool:1, set screw M3x3 : 2, double-sided

tape: 1, front cover: 1, hexagonal wrench (size :

3 mm) :1, hexagonal wrench (size : 1.5 mm): 1, positioning

pins: 3, clay: 1, MDX-20/15 user's manual: 1 |

| Modeling

Functions |

| Tool

chuck |

6

mm or 1/8 in. tool chuck included |

| Spindle

motor |

10W

(DC motor) |

| Software

resolution |

0.025

mm/step (0.000984 in./step) |

| Mechanical

resolution |

0.00625

mm/step (0.000246 in./step) |

| Revolution

speed |

6500

rpm |

| Feed

rate |

0.1

to 15 mm/sec. (0.00393 to 9/16 in./sec.) |

|

Acceptable

material |

Wood,

Plaster, Resin (modeling wax, styrenform), Chemical

wood, Aluminum (A5052 according to JIS),Brass |

| Acceptable

tool |

Endmil,

Drill |

| Scanning

Functions |

| Sensor |

Roland

Active Piezo Sensor (R.A.P.S.)Probe length 60 mm (2-5/16

in.), tip bulb diameter 0.08 mm (0.00315 in.) |

| Scanning

method |

Contacting,

mesh-point height-sensing |

| Scanning

pitch |

|

| (Dr.

PICZA) |

X/Y-axis

directions -- 0.05 to 5.00 mm (0.002 to 0.20 in.)

|

| Scanning

speed |

(settable

in steps of 0.05 mm (0.002 in.)) |

| Exportable

file formats |

Z-axis

direction -- 0.025 mm (0.000984 in.) |

| |

4E5

mm/sec. (1/8E/16 in./sec.) |

| |

DXF,

VRML, STL, 3DMF, IGES, |

| |

Grayscale,

Point Group and BMP |

|