| Model |

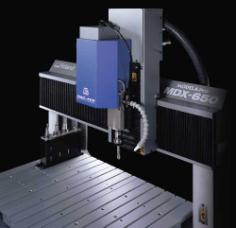

MDX-650 |

|

T-slot

(XY) table size |

700 mm x 480 mm (27-1/2 x 18-7/8 in.) |

|

Max.

cuttng area* |

650 mm (X) x 450 mm (Y) x 155 mm (Z)

(25-9/16(X) x 17-11/16(Y) x 6-1/16(Z) in. ) |

|

XYZ

motor |

AC servo motor |

|

Feed

rate |

X, Y, Z-axis: Max. 85 mm/sec. (3-3/8 in./sec.) |

|

Acceleration |

0.3G, 0.1G, 0.05G |

|

Software

resolution |

[When RML-1 has been selected] 0.01 mm/step (0.00039

in.)

[When NC codes has been selected] 0.001 mm/step (0.000039

in.)

Note that the measurement unit for positioning coordinates

is 0.01 mm/step(0.00039 in.). |

|

Mechanical

resolution |

0.001 mm/step |

|

Spindle

motor |

DC brushless motor Max. 400W (when with high-torque

spindle) |

|

Revolution

speed |

[High torque spindle and High precision spindle] 3000

to 12000 rpm

[High speed spindle] 5000 to 20000 rpm

(Variable manually or by the command set) |

|

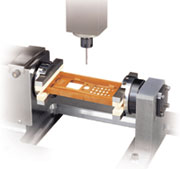

Tool

chuck |

Collet or Cutter holder system |

|

Positioning

accuracy |

±0.1 mm (0.00394 in.) / 300 mm (11-13/16 in.) (Under

no-load conditions) |

|

Repeat

accuracy |

±0.05 mm (0.00197 in.) (Under no-load conditions) |

|

Origin-point

reproducibility

(When the power is switched on/off) |

±0.08 mm (0.00315 in.) |

|

Possible

table load weight |

[0.3G] 12 kg (26.5 lb.) or less [0.05G] 20 kg (44.1

lb.) or less |

|

Interface |

Parallel (in compliance with the specification of

Centronics)

Serial (under RS-232C standard) |

|

Buffer

size |

2 Mbyte

(Replot buffer: [RML-1] 2 Mbyte [NC codes] Max. 2 Mbyte

(end-user setting)) |

|

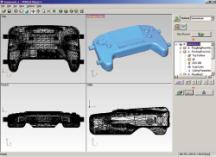

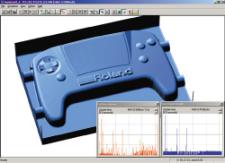

Instruction

system |

RML-1 (mode1, mode2) or NC codes supported by the

MDX-650 (Selectable through display operation) |

|

Power

consumption |

6.5 A / 117 V 3.5 A / 220 to 230 V 3.5 A / 230 to

240 V |

|

Weight

/ Dimensions |

120 kg (264.5 lb.) / 930 mm (W) x 1085 mm (D) x 870

mm (H)

(36-5/8(W) x 42-3/4(D) x 34-5/16(H) in. ) |

|

Operation

temperature / Operation humidity |

5 to 40°C (41 to 104°F) / 35 to 80% (no condensation) |

|

Accessories |

T-slot clamps: 4, Spanner: 1 (10 mm (3/8 in.)), Z0

position sensor: 1, Power cord: 1, Belt for high-torque

spindle: 1, Key connector: 1,Roland Software Package CD-ROM:

1, Hexagonal wrench: 1, Ferrite core: 1, NC-code PROGRAMMER'S

MANUAL: 1,USER'S MANUAL: 3 (1. Setup & Maintenance,

2. Cutting Using the Included Software, 3. Cutting Using

NC codes) |