| |

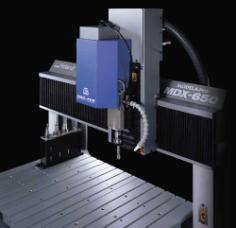

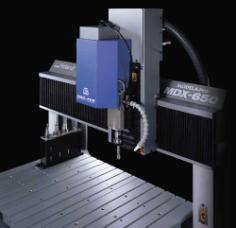

MDX-500/650:

(3/4-axis CNC Milling and 3D Engraving Machine)

With the strong horse power, MDX-500/650 is able

to handle a wide variety of materials. As MDX-500/650 is a highly

stable and inexpensive CNC milling and 3D engraving machine, many

manufacturers, for example, those in the watch-making and silverware

products industries, have purchased it to produce their products

directly.

|

|

|

| MDX-500 |

MDX-650 |

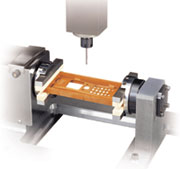

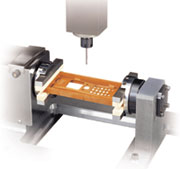

Users of MDX-650 can select the optional rotary

axis to perform rapid prototyping. Since the controller of MDX-650

can directly link up with the ArtCAM Jewellery Edition, it automates

the whole production process and ensures that work pieces can be

completed without errors.

|

|

The convenient

operation interface of the controller and its LCD display

let you control the speed and the coordinates easily. |

|

|

With

the NC programming system and the optional rotary axis, the

MDX-650 is able to produce faster, more accurate prototypes.

Jewellery, rings

and other products can be produced easily at one time.

|

Application

software included

|

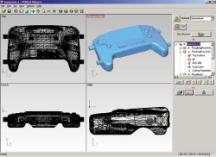

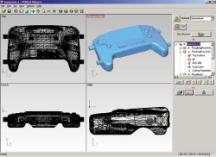

MODELA

PLAYER 4

This is

the latest version of MODELA PLAYER. Experienced users can

make modifications flexibly by utilizing its professional

CNC programming function.

New MODELA

PLAYER can support different cutting tools and milling methods,

and the fully automatic rapid prototyping technique. (with

the optional rotary axis)

|

|

|

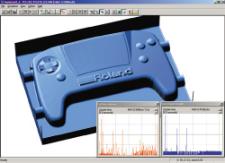

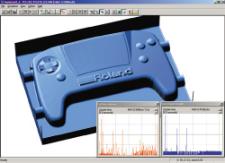

Virtual MODELA

Virtual MODELA provides a quick preview of

the entire milling operation. This powerful feature eliminates

milling errors, enables simulation of finished shapes and

estimates production time. |

|

Machining Quality

|

|

With

the optional rotary axis, work pieces with irregular and complicated

shapes can be produced at one time. |

|

|

This

picture depicts a chemical wood. The same technique can be applied

to ABS, polyurethane, wax, aluminum, brass and other non-ferrous

metals. |

|

|

The

MDX-650 can create high quality molds and dies using ordinary

metals. |

Making

of Jewellery Prototypes

|

|

A

MDX-650 device on the steel desk. |

|

|

Rings

can be completely produced while the optional rotary axis

is in use. |

|

|

The

MDX-650 can mill 10 to 12 rings at one time. |

|

|

Remove

unwanted parts of the ring after milling.

Once the

whole ring is completed, it can be further processed by the

lost wax casting method. |

Feature

| Model |

MDX-650 |

|

T-slot

(XY) table size |

700 mm x 480 mm (27-1/2 x 18-7/8 in.) |

|

Max.

cuttng area* |

650 mm (X) x 450 mm (Y) x 155 mm (Z)

(25-9/16(X) x 17-11/16(Y) x 6-1/16(Z) in. ) |

|

XYZ

motor |

AC servo motor |

|

Feed

rate |

X, Y, Z-axis: Max. 85 mm/sec. (3-3/8 in./sec.) |

|

Acceleration |

0.3G, 0.1G, 0.05G |

|

Software

resolution |

[When RML-1 has been selected] 0.01 mm/step (0.00039

in.)

[When NC codes has been selected] 0.001 mm/step (0.000039

in.)

Note that the measurement unit for positioning coordinates

is 0.01 mm/step(0.00039 in.). |

|

Mechanical

resolution |

0.001 mm/step |

|

Spindle

motor |

DC brushless motor Max. 400W (when with high-torque

spindle) |

|

Revolution

speed |

[High torque spindle and High precision spindle] 3000

to 12000 rpm

[High speed spindle] 5000 to 20000 rpm

(Variable manually or by the command set) |

|

Tool

chuck |

Collet or Cutter holder system |

|

Positioning

accuracy |

±0.1 mm (0.00394 in.) / 300 mm (11-13/16 in.) (Under

no-load conditions) |

|

Repeat

accuracy |

±0.05 mm (0.00197 in.) (Under no-load conditions) |

|

Origin-point

reproducibility

(When the power is switched on/off) |

±0.08 mm (0.00315 in.) |

|

Possible

table load weight |

[0.3G] 12 kg (26.5 lb.) or less [0.05G] 20 kg (44.1

lb.) or less |

|

Interface |

Parallel (in compliance with the specification of

Centronics)

Serial (under RS-232C standard) |

|

Buffer

size |

2 Mbyte

(Replot buffer: [RML-1] 2 Mbyte [NC codes] Max. 2 Mbyte

(end-user setting)) |

|

Instruction

system |

RML-1 (mode1, mode2) or NC codes supported by the

MDX-650 (Selectable through display operation) |

|

Power

consumption |

6.5 A / 117 V 3.5 A / 220 to 230 V 3.5 A / 230 to

240 V |

|

Weight

/ Dimensions |

120 kg (264.5 lb.) / 930 mm (W) x 1085 mm (D) x 870

mm (H)

(36-5/8(W) x 42-3/4(D) x 34-5/16(H) in. ) |

|

Operation

temperature / Operation humidity |

5 to 40°C (41 to 104°F) / 35 to 80% (no condensation) |

|

Accessories |

T-slot clamps: 4, Spanner: 1 (10 mm (3/8 in.)), Z0

position sensor: 1, Power cord: 1, Belt for high-torque

spindle: 1, Key connector: 1,Roland Software Package CD-ROM:

1, Hexagonal wrench: 1, Ferrite core: 1, NC-code PROGRAMMER'S

MANUAL: 1,USER'S MANUAL: 3 (1. Setup & Maintenance,

2. Cutting Using the Included Software, 3. Cutting Using

NC codes) |

A-axis

Feature

| Model |

ZCL-650 Rotary Axis Unit |

| Supported

workpieces |

Resins such as chemical wood and modeling wax (metal

not supported) |

|

Max.

workpiece size |

Items within range of maximum diameter 200 mm* x 410

mm (W)

(diameter 7-7/8 in.* x 16-1/8 in. (W))

*Maximum clampable thickness is 50 mm (2 in.) |

| Clamping

method |

Set-screw type (Cylinders cannot be mounted.) |

| X-axis

effective stroke |

385 mm (15-1/8 in.) |

| Z-axis

effective stroke |

155 mm (6-1/16 in.) |

| Maximum

angle of rotation |

1080 degrees (3 rotaions) |

| Maximum

speed |

20 rpm |

| A-axis

mechanical resolution |

0.0027 degrees (2.3micron m with workpiece of 100

mm in diameter) |

| Static

precision |

Rotation backlash: 3 minutes Eccentricity: 0.3 mm

(0.012 in.) or less |

| Height

of center of rotation |

123 mm (4.84 in.) from top surface of slider |

| Maximum

workpiece weight |

8 kg (17.6 lb.) |

| Maximum

workpiece moment of inertia |

0.02 kgm2 |

| Unit

weight / Unit external dimensions |

12 kg (26.5 lb.) / 725 (W) x 270 (D) x 170 (H) mm

(28-9/16 (W) x 10-5/8 (D) x 6-11/16 (H) in.) |

| Control

methods |

4-axis control, 3-axis simultaneous control |

|

Included

items |

Rotary axis unit, cable clamp, hexagonal wrenches

(6 mm: 1, 3 mm: 1), Y-center detection pin (diameter 6 mm),

screws: 4, cap screws: 4, washers: 4, spacers: 4, and slider

retainer |

|